Affordable Flexibility and Output

AMP 3K and AMP 5K Terminators terminate wire using reeled terminals and contacts, and are designed for customers requiring the increased output and quality of a semiautomatic machine at a competitive price. By incorporating the most commonly requested features as standard and offering a long list of optional equipment, these terminators offer flexibility to meet the specific needs of various applications at the lowest possible cost.

5,000

5,000 lb max crimp force

DC

DC motor design

0.400

0.400 cycle time

Features

- Jog capability

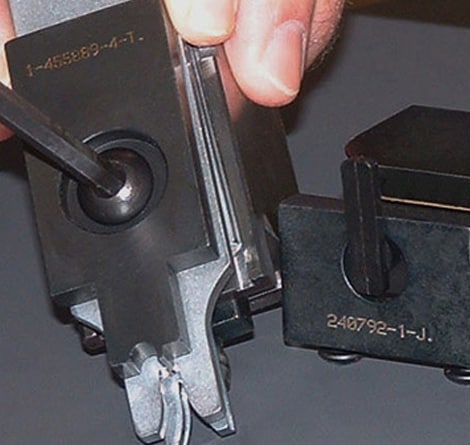

- Accepts heavy duty mini style applicators

- Tool-less removal of applicators and guards for quick and simple maintenance and product change over

- Quiet and fast operation – 80/76 dBa and cycle time less than 0.400 seconds

- Universal electrical input – 100-240 VAC, 50/60 Hz

- Wide range of optional equipment such as tool-less precision crimp height adjust, batch counter, CQM capability and work light

- Cannot be operated during normal production with guards open

- 3,000 lb [1361 kg] max. crimp force (AMP 3K)

- 5,000 lb [2268 kg] max. crimp force (AMP 5K)

Advantages

- One applicator platform – modular family design

- Two styles with three feed options: mechanical, pneumatic, and servo

- Same wire crimper, insulation crimper, and anvil used on both applicator styles

- Open architecture for design flexibility

- Finer incremental crimp height adjustment

Design

The AMP 3K and AMP 5K Terminators use a DC motor with gearbox drive. The result is a small-footprint design that is fast and quiet. Cycle time is less than 0.400 seconds with an operation sound level of 76 dBa (AMP 3K) or 80 dBa (AMP 5K).

A wide range of optional equipment is available to meet your specific application requirements. With options including tool-less precision crimp height adjust, CQM capability, batch counter, and a work light, the AMP 3K and AMP 5K can be tailored to the specific application requirements without inflating the price for unwanted features.

Stripping Module

Optional

The combination of the Stripping Module with the AMP 3K, AMP 5K or Model G II Terminators can provide you with an economic and proficient method of stripping the wire and crimping terminals on the same machine.

A special machine is no longer needed for just stripping the wire. The wires are stripped moments before crimping, which means that there is virtually no chance of damaging the wire conductors during handling or storage. Wire placement accuracy is also improved because once the wire is fed into the start sensor, thestripping module does the rest.

- Field installed or available as one unit from the factory

- Accepts end- and side-feed HDM applicators – 32-14 AWG (with slight modification)

- Three modes of operation – crimp only, strip only, or strip and crimp

- Footswitch or sensor activated

- Fast applicator changeover and easy adjustments

- Air blast ejects slugs into a collection tray

- Titanium nitride coated strip blades for longer life

Crimp Quality Monitor (CQM II)

Optional

Crimp height is the best non-destructive way to ensure meeting the stringent mechanical and electrical properties of the crimp. Crimp height is one of the five different process analysis methods featured in the new CQM II.

The CQM II features easy-to-use, intuitive menus along with enhanced monitoring and graphing. Another major enhancement is the ability to use CQM II on non-TE terminators. The unit can standardize and provide TE Crimp Quality monitoring across your production area by being versatile, precise, and convenient.

Defective Crimp Cut

Optional

With the help of our CQM II, defective crimp cut technology can immediately detect when a bad crimp occurs and cut off the crimped terminal to ensure bad crimps don‘t accidentally pass to the next step in your wire harness manufacturing.

Ordering Information

| Description | Stroke | Baseplate | Part # |

|---|---|---|---|

| AMP 3K/40 CE EL Terminator | 40 MM | AMP Style | 2161400-5 |

| AMP 5K/30 CE Universal Jam Terminator | 30 MM | Universal JAM | 2-2161500-1 |

| AMP 5K/30 CE Universal Jam (W/ CQM II) |

30 MM | Universal JAM | 2-2161500-2 |

| AMP 5K/40 CE Terminator | 40 MM | AMP Style | 2161500-1 |

| AMP 5K/40 CE Terminator (W/ CQM II) |

40 MM | AMP Style | 2161500-2 |

| AMP 5K/30 CE Terminator | 30 MM | AMP Style | 3-2161500-1 |

| AMP 5K/30 CE Terminator (W/ CQM II) |

30 MM | AMP Style | 3-2161500-2 |

| AMP 5K/40 CE Terminator (W/ Oversized Guard, AF) |

40 MM | AMP Style | 4-2161500-0 |

| AMP 5K/40 CE Thru-Splice Terminator | 40 MM | Thru Splice | 2161300-1 |

| AMP 5K/40 CE Thru-Splice Terminator (W/ CQM II) |

40 MM | Thru Splice | 2161300-2 |

| AMP 5K/40 CE (W/Stip Module) |

40 MM | AMP Style | 2161700-4 |

| AMP 5K/40 CE (W/ Strip Module and CQM II) |

40 MM | AMP Style | 2161700-5 |

| 5K Atlantic Terminator (W/ Defective crimp cut module) | 40 MM | AMP Style | 2362229-1 |

| 5K Pacific Terminator (W/ Defective crimp cut module) | 30 MM | AMP Style | 2362229-2 |