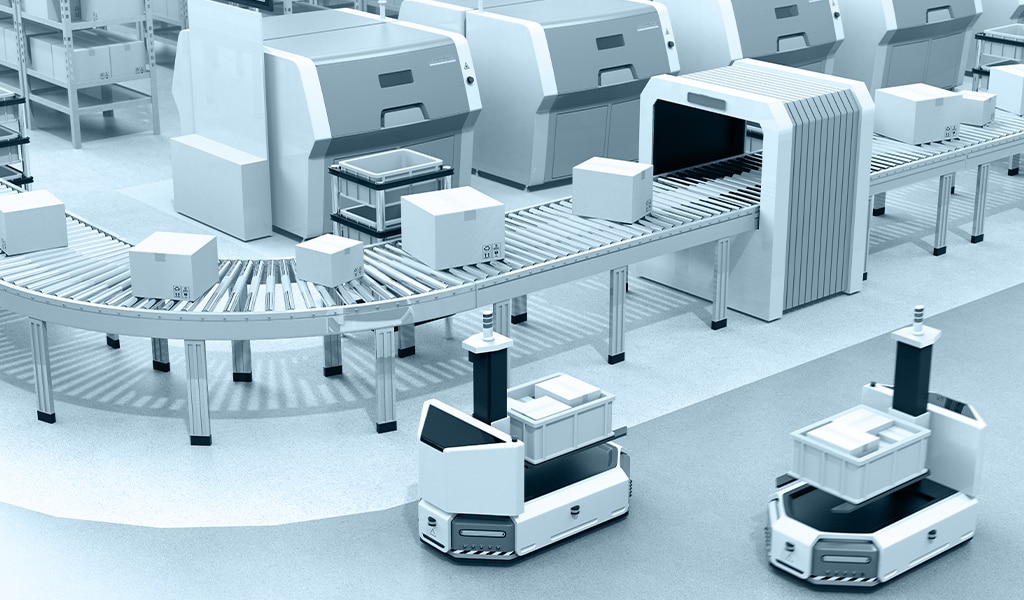

AGV Charging Technology

To meet the growing demand for warehouse automation, AGV manufacturers must provide more powerful, longer-lasting technologies. TE experts can help.

Powerful, Flexible Charging Connections

Support Uninterrupted Operation

With the growing demand for mobile robots in warehouse automation, rugged, powerful, and flexible connectivity solutions that provide long product life are a must. A single broken connection can bring warehouse operations to a halt — and the lost time can be costly. Connectivity solutions must support uninterrupted operations along with providing efficient charging capabilities and battery management solutions. Learn more about AGV trends and how connector solutions are evolving to meet the growing demand and deliver improved performance.

Battery Management

In warehouse automation, the reliability of forklifts, AGVs, AMRs, and ASRS is crucial. The steady operation of these warehouse vehicles depends on a battery management system (BMS), which tracks battery usage, temperature, and charging status. Since battery connectors are one of the most vulnerable parts of the system, the use of rugged, high-quality connections is key to avoiding downtime. Our products for battery management are designed and engineered to work in harsh environments with high vibration. They help enable the miniaturization needed for increasingly compact batteries and battery systems.

Charging Stations

Where there are batteries, there must be charging. Speed is key in warehouse automation, and the various robots operating in a warehouse cannot sit idly for hours on end to power up. Therefore, charging currents tend to be high in warehouses, ranging from 40 A to 300 A. Reliable power connectors simplify assembly efforts and help reduce safety hazards, and TE’s products can help improve power distribution capabilities between the charger, battery, and drive system. Our connectors offer multiple contact points to support high-vibration tolerance and our large product portfolios serve a wide variety of uses and compact designs.